Most of us are curious about the quality of jeans or how they are made. For those who know, jeans are made from a fabric called denim. But is that all there is to it? In this article, we will discuss what denim fabric is, the main characteristics of denim fabric, and how it is made.

What is Denim Fabric

Denim is a coarse, thick, yarn-dyed twill cotton fabric with a colored warp and white weft. The warp threads are usually dyed indigo, while the weft threads are typically light grey or bleached white. Denim is also known as indigo-dyed workwear fabric.

Denim originated in the American West, where it was used by cowboys for making clothes, which is how it got its name. The warp yarns are dyed using a slasher dyeing method, with common thread counts being 80 tex (7s), 58 tex (10s), and 36 tex (16s). The weft yarn counts include 96 tex (6s), 58 tex (10s), and 48 tex (12s). Denim typically uses a 3/1 twill weave, but variations like broken twill, plain weave, or crepe weave are also used. The raw fabric undergoes shrink-resistant treatment, resulting in a lower shrinkage rate compared to other fabrics. Denim is dense, thick, brightly colored, and has a clear weave pattern. It is suitable for making men's and women's jeans, denim jackets, denim vests, and denim skirts.

Main Features of Denim Fabric

1. Durable Texture

Denim fabric uses a twill weave structure, which provides high tensile strength and abrasion resistance. It can withstand significant pulling and friction without easily wearing out or tearing. Therefore, denim clothing is well-suited for outdoor activities and rough work environments.

2. Deep and Vivid Colors

Denim fabric boasts vibrant and rich colors that do not fade easily. This is due to a unique dyeing process that allows the pigment to penetrate deep into the fibers, ensuring long-lasting color. Additionally, dark-colored denim can effectively conceal body imperfections, offering a slimming effect.

3. Firm Handfeel

Denim fabric has a distinct firm texture, feeling coarse and substantial to the touch. After multiple wears, the fabric gradually becomes softer due to friction, yet it retains its original texture.

The Manufacturing Process of Denim Fabric

The denim manufacturing process includes several stages, each contributing to the quality and appearance. So, there are stages that provide an overview of the typical denim manufacturing process.

1. Selection of raw material: Cotton cultivation

Typical source of denim fabric material starts with the cultivation of cotton which is harvested and ginning to extract raw fibers. Some other fibers may be included in the percentage as spandex or polyester to add stretch and durability. Long staple cotton is crucial in quality and is preferred for strength and smoothness.

2. Processing into yarn: Spinning and dying

Cotton fibers are cleaned and combed to remove the impurities and align fiber stand in various machines and processes. This is then spun into yarn on machines called ring-spun or open-end spinning. The yarn is dyed to indigo blue and other desired colors. Also, this dying process involves various machines using different techniques including rope dyeing and slasher dyeing.

3. Processing into weaving: Fabric

(1) Weaving Technologies in Denim Manufacturing

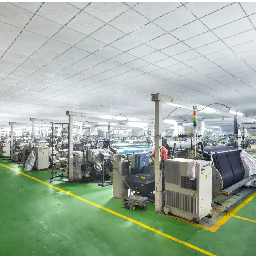

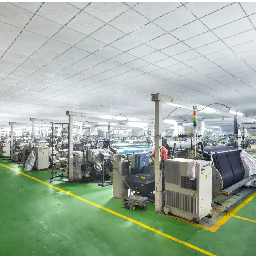

Denim fabrics are produced using four main weaving technologies: shuttle looms, projectile looms, rapier looms and air-jet looms.

l shuttle looms

The shuttle loom is the oldest traditional method of producing dense, durable fabrics. However, this method is time-consuming and laborious, and cannot keep up with the speed of modern production.

l Projectile looms

Projectile looms, introduced in the 1950s, use a shuttleless system that uses small metal bullets or projectiles to pass the weft yarn through the warp yarn. This method is faster than a shuttle loom and produces a smoother surface.

l Rapier looms

Rapier looms use flexible rods to thread the weft through the warp. This method results in minimal yarn breakage and produces a uniform fabric.

l Air-jet looms

Most efficient in terms of speed and efficiency, air jet looms use compressed air for weft insertion. It produces fabrics of the highest quality with the fewest imperfections.

(2) Weaving of Denim

l Load the prepared warp and weft yarns into the loom.

l Next, thread the warp yarns through a series of heddles, which help control the movement of individual warp threads.

l The heddles are attached to frames called harnesses, which move up and down during the weaving process.

l The warp yarns then pass through the reed, which helps maintain the spacing of the warp threads.

l The weft yarn is then inserted by a shuttle, which passes it between the raised and lowered warp threads.

l A comb-like tool called a beater is used to firmly press the weft yarn into the previously woven fabric.

l The harnesses are then rearranged to create different patterns, and the process is repeated until the desired length of denim is woven.

l The woven denim is then removed from the loom and inspected for quality control.

l Finally, the fabric is rolled onto a beam for the finishing stage.

(3) Different Weaving Patterns and Designs

Weaving patterns and designs play an indispensable role in the appearance of denim fabric.The two most common weaving methods for denim are plain weave and twill weave.

l Plain Weave

Plain weave is a basic over-and-under pattern that creates a smooth, flat surface with minimal texture and stretch. It is typically used for lightweight denim and serves as a foundation for painting and coating.

l Twill Weave

Twill weave involves passing the weft thread over and under the warp threads, forming diagonal ridges on the surface. Twill denim has a diagonal ribbed effect, making it more elastic, softer to the touch, and providing a better surface feel.

In conclusion, denim is a durable, colorful, and firm fabric, making it ideal for jeans and other workwear. Originating in the American West, denim's unique qualities stem from its indigo-dyed yarns and twill weave structure. The manufacturing process involves several steps: cotton cultivation, yarn spinning and dyeing, and weaving using various technologies like shuttle, projectile, rapier, and air-jet looms. The fabric's strength, vibrant colors, and firm texture are due to the meticulous process, from selecting raw materials to the final weaving stages. Denim's resilience and aesthetic appeal make it a popular choice for various apparel, embodying both functionality and style.

English

English Español

Español